Design

Home | Design

Our experience is at your disposal

Design is a crucial step that will affect quality, efficiency, and maintenance costs during the life cycle of molds. It requires attention and experience to achieve and ensure qualitatively and quantitatively high-performing productions over time.

Our highly skilled and experienced team of technicians will develop your idea with you and make it feasible in just a few steps, providing all the support and suggesting the optimal solutions at every step.

Feasibility analysis

We listen to your needs and strive to identify the most efficient solutions that can meet them. At this stage we thoroughly analyze the requirements, the intended use of the product, and the details necessary for its implementation, to verify and define the feasibility of the project.

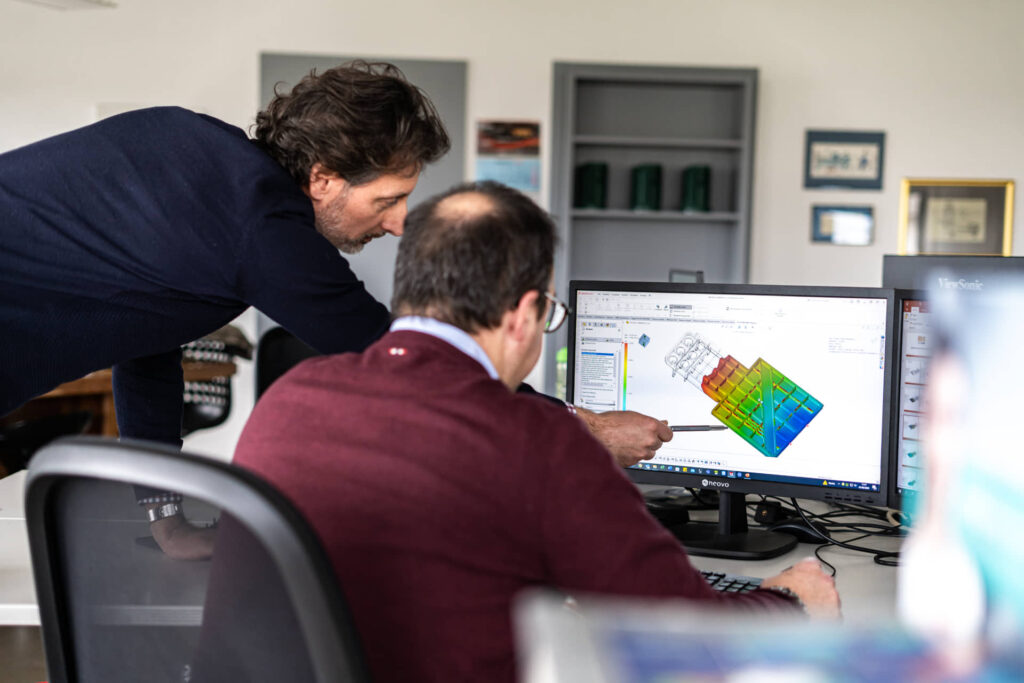

Co-Design, study, process simulation and material selection

We use state-of-the-art cad software to reproduce molding operations. 3D simulations allow us to virtually verify every small detail, highlight any critical issues and areas for improvement right away, and solve them as early as the design phase. Where necessary we prepare fill and deformation analyses.

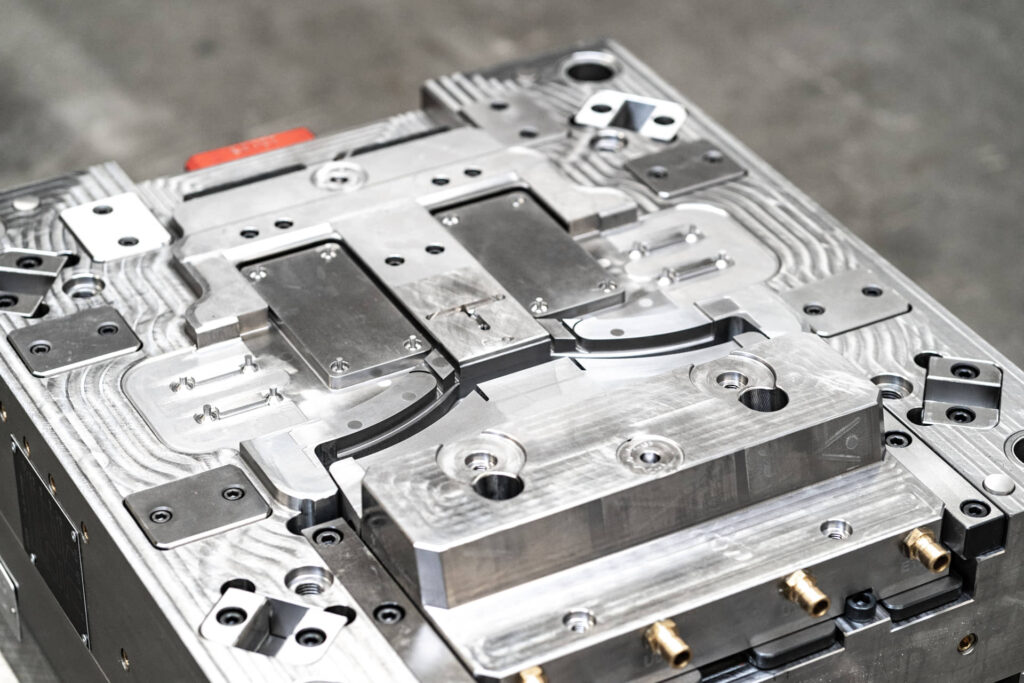

Mold making and prototyping

We design and build molds in cooperation with first-rate tooling companies, Italian, reliable partners who have long cooperated with our company in mold making. We build pilot molds at the customer’s request. The pilot mold is usually made to optimize and define the construction criteria and functionality of a multi-cavity mold by improving its performance.