Molding

Home | Production | Molding

Expertise and technology in industrial molding

Whether it is single-material molding, with plastic and metal (co-molding) or bi-material molding, this processing, in its 3 versions, has been the core business of our company for more than 70 years.

Our strength lies in the combination of state-of-the-art equipment and experienced production staff.

This combination of skills and technology allows for high production flexibility and maximum precision for a perfect finish on every part produced.

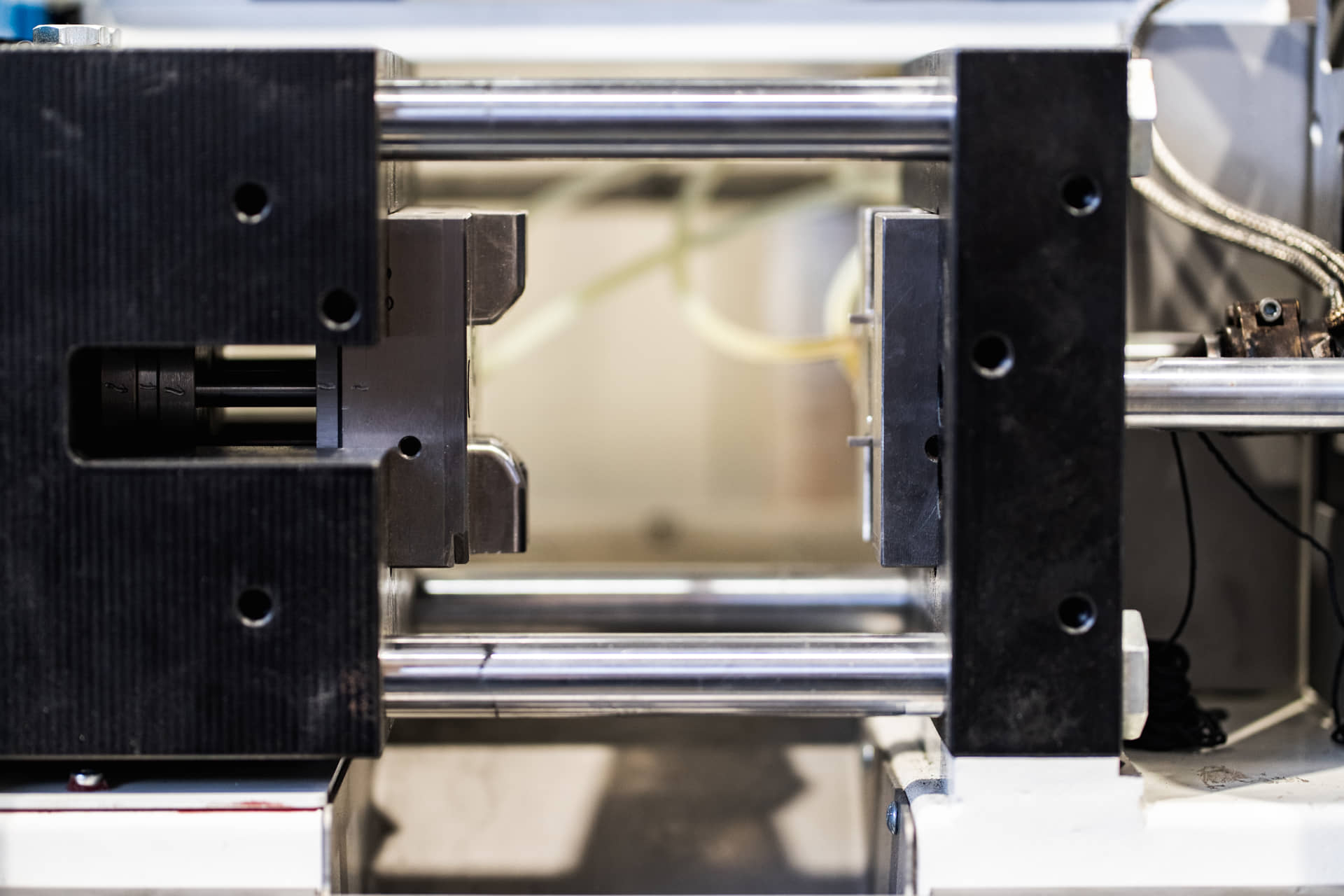

Single-material molding on horizontal press

50 horizontal injection molding machines with tonnage ranging from 10 to 700 Tons equipped with manipulators that place the part neatly on a conveyor belt, facilitating quality control and preventing deformation from falling onto parts.

They can produce, with a wide variety of materials, technical parts within the range of 2gr to 3Kg per mold.

presses

Horizontal

Tonnage from

10 to 700 Tons

Production from

2g to 3 kg

Bimaterial molding

3 bimaterial presses equipped with rotary table, capable of molding two types of material in the same article in specific mold surfaces.

Overmolding makes it possible to obtain items that meet:

- aesthetic requirements (e.g., pieces with two different colors, pieces with soft feel, pieces made of regenerated polymer “ennobled” with new material cover);

- sealing requirements (e.g., pressure resistance);

- performance requirements (e.g., resistance to critical temperatures, resistance to particular chemicals).

presses

Horizontal bimaterial

Table

Rotating

Automation

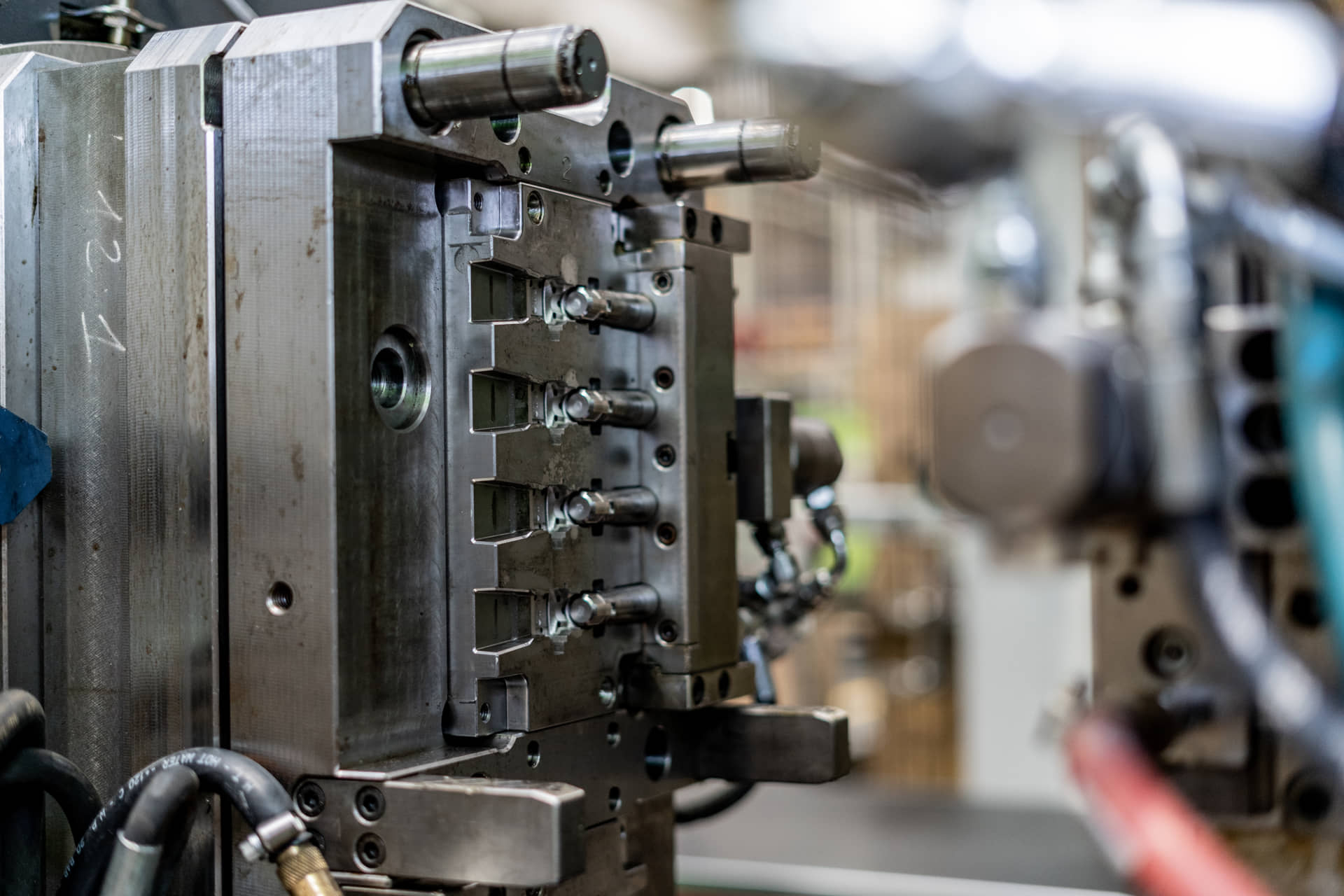

Costamping

18 presses (15 horizontal and 3 vertical with two- or three-station rotary table), implemented by loading islands, control and unloading automated inserts, which are essential to achieve process repeatability while ensuring maximum quality standards, thanks to cameras and monitors for the 100% visual inspection by each individual printed.