We take care of your mold

MAINTENANCE

In Primis: the timeliness

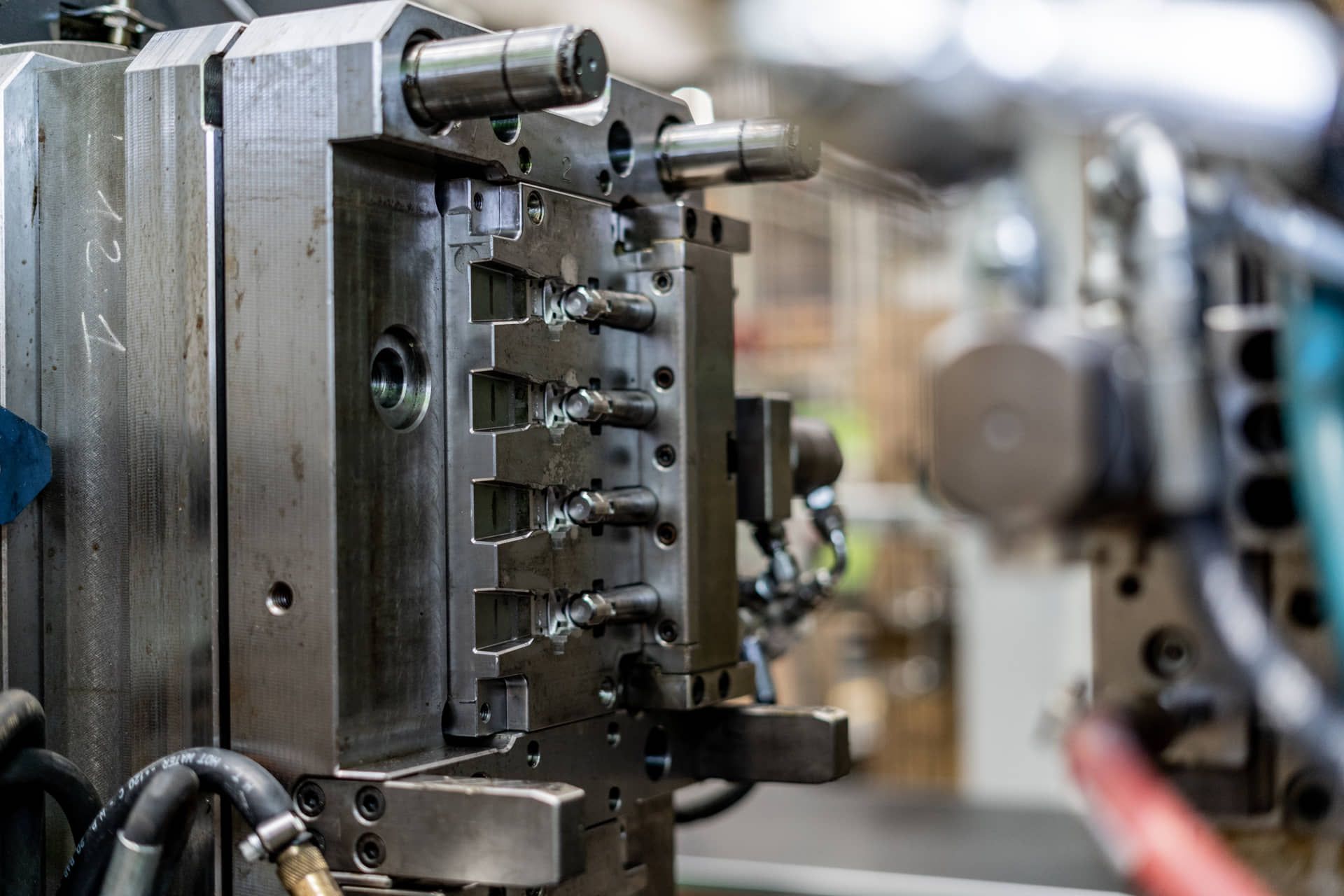

To quickly respond to any repair needs, we perform immediate, extraordinary maintenance on molds in our specialized tool shop, in consultation with the customer. We understand the importance of each component of your mold and have a thorough understanding of its specific characteristics, allowing us to prioritize repairs accordingly. Furthermore, our team is equipped with cutting-edge precision repair equipment, including a state-of-the-art laser welding machine, allowing us to perform just-in-time repairs. This approach not only ensures rapid and effective service, but also significantly reduces downtime. As a result, we are able to minimize costs associated with any production downtime, thus ensuring the operational continuity of our customers' businesses.

Maximum efficiency

We want your molds to always be at peak efficiency to ensure the highest possible quality in your production processes. For this reason, we have a highly specialized in-house workshop, which dedicates over 5,000 hours per year to directly managing mold care. This team is responsible for scheduling routine maintenance, which is performed by highly professional maintenance technicians, each with many years of practical workshop experience. Our focus on maintenance is not limited to occasional repairs, but focuses on preventative and scheduled maintenance. This strategic approach not only helps preserve the mold's lifespan, but is also crucial for preventing breakages, minimizing costs related to poor quality, and ensuring productivity is maintained over time. In this way, we ensure your molds can operate at maximum efficiency, delivering optimal and consistent results.

Custom modifications and designs

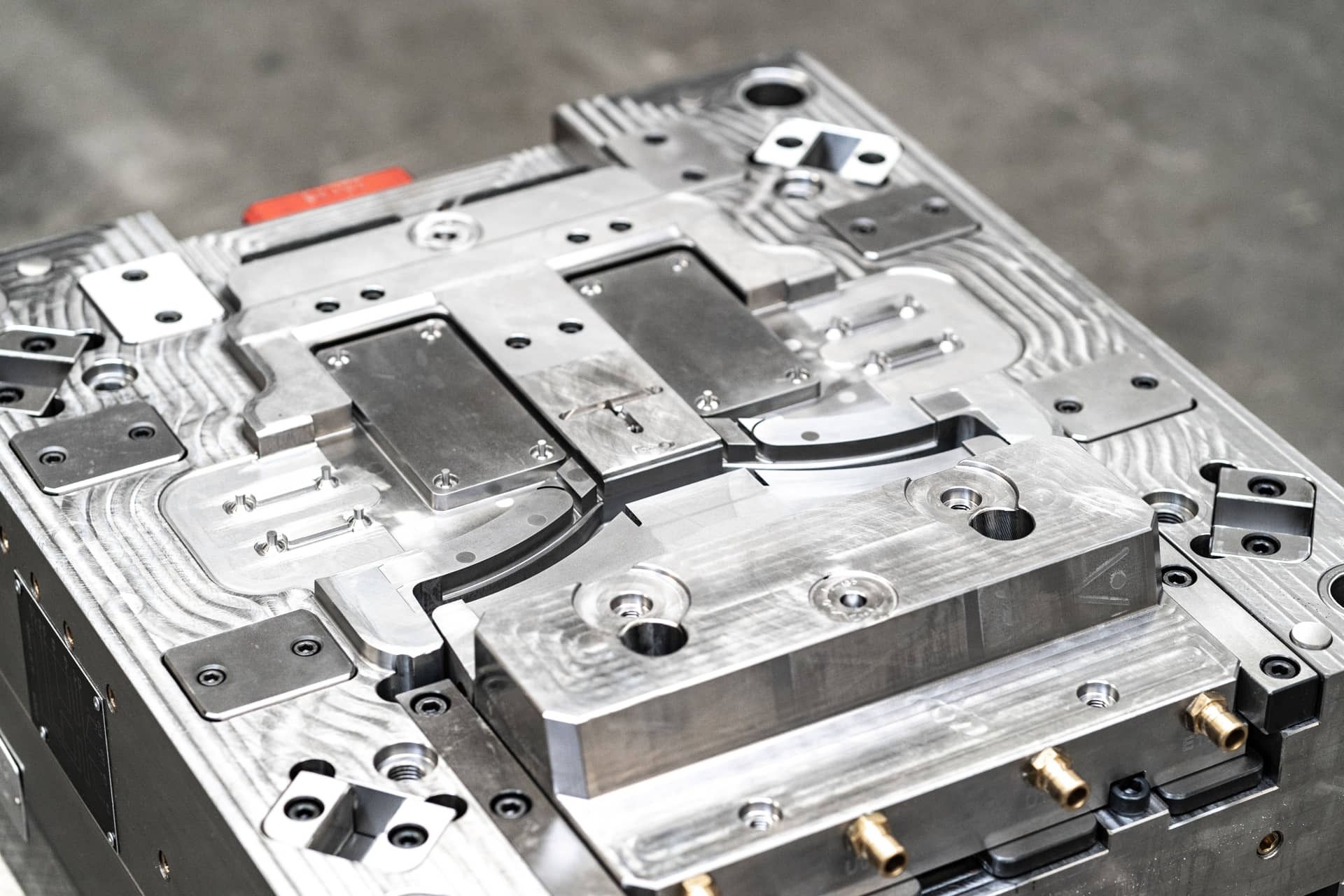

At the client's request, we design and implement mold modifications to meet changing needs as they emerge over time. This process includes not only creating new versions of the molds, but also adding or replacing specific inserts to increase productivity and ensure optimal efficiency. We also handle the maintenance and, if necessary, replacement of hot runners, which are essential for the proper functioning of the process. Finally, we restore injection points, ensuring that every aspect of the mold meets the client's needs and market dynamics, ensuring consistently up-to-date results.