PRODUCTION

Ultrasonic welding

Advantages of ultrasonic welding

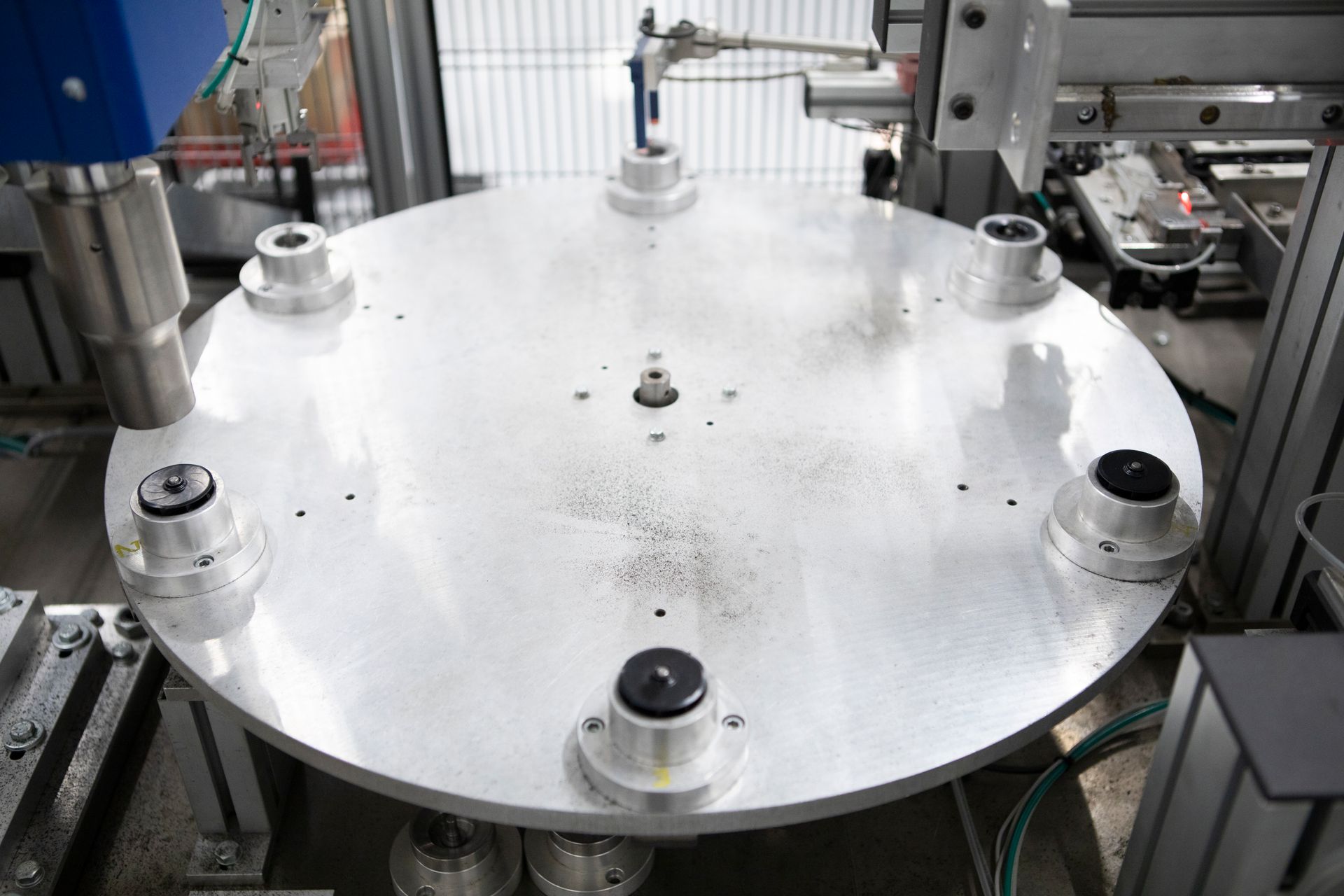

Thanks to integration with automated loading and unloading systems and continuous monitoring via dedicated software, every stage of the process is controlled down to the smallest detail. Welding parameters are constantly monitored to meet the highest quality standards, ensuring uniformity and reliability in every production batch. With these cutting-edge technologies, Plastica Nardon offers its customers ultrasonic welding of the highest precision, ideal for applications in the automotive, electronics, household appliance, and mechanical sectors, where safety, performance, and quality are paramount.

Advanced technology for joining plastic materials: ultrasonic welding

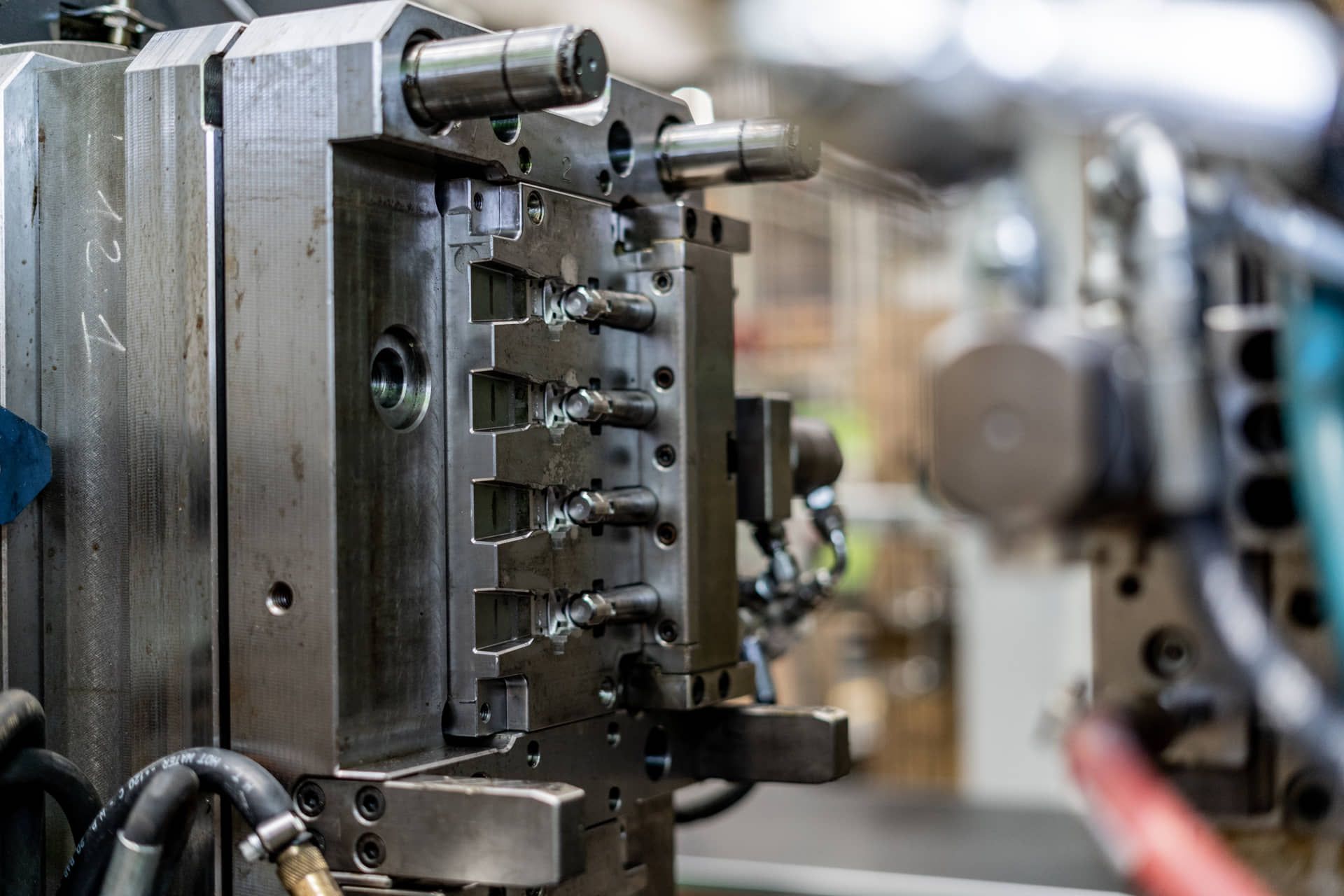

In our production department, we employ 7 ultrasonic welding machines, 4 of which are equipped with dedicated automation, enabling us to perform extremely precise and repeatable processes. This technology allows for the stable joining of plastic components and the reliable insertion of metal inserts directly into the molded parts, ensuring a solid, clean, and long-lasting result. Ultrasonic welding is an ideal solution for assembling complex plastic components, as it eliminates the need for glues or screws, reduces production times, and ensures a superior aesthetic quality of the finished product.

7

Ultrasonic Welders

Loading / unloading

Automated