Third-party molding of technical plastic items

PRODUCTION

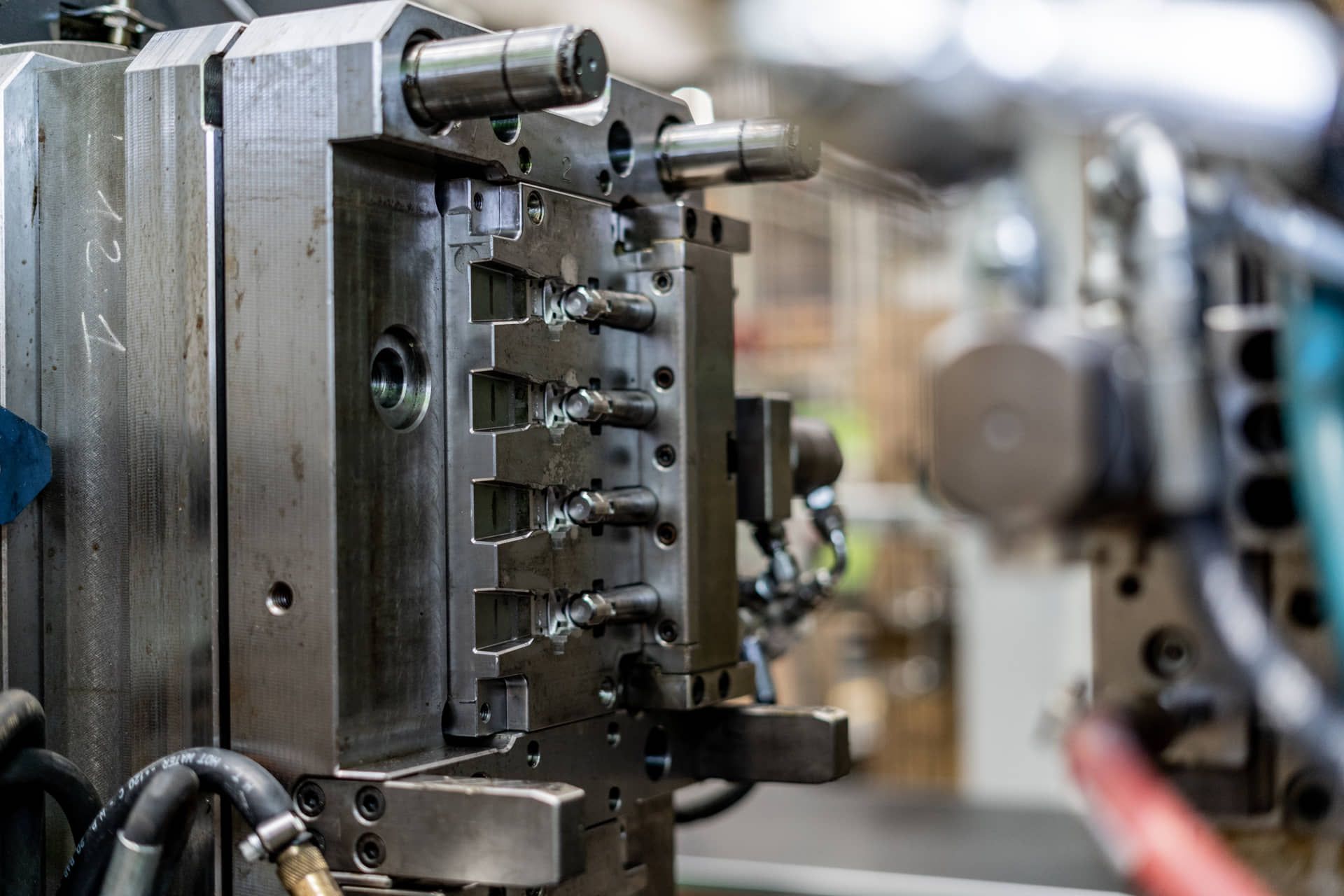

Single-material molding on a horizontal press

The 50 available horizontal injection molding machines range in tonnage from 10 to 700 tons. These machines are equipped with sophisticated manipulators that position the parts neatly on a conveyor belt. This system not only facilitates quality control but also helps prevent any deformations that could occur due to falling parts. Furthermore, these machines can produce technical parts weighing from 2 grams to 3 kg per molding cycle using a wide range of materials, ensuring flexibility and precision in production.

Expertise and technology in industrial molding

Whether it's single-material molding, plastic and metal molding through co-molding, or two-material processing, this sophisticated technique, in its three distinct versions, has been our company's core business for over 70 years, a milestone that demonstrates our solidity and dedication to the industry. Our strength lies primarily in the synergistic combination of cutting-edge equipment and the highly skilled production staff, who boast ongoing training and years of consolidated expertise. This combination of technical expertise and modern technology allows us to guarantee high production flexibility, reducing production times and optimizing processes. Furthermore, it ensures maximum precision for a flawless finish on every single piece produced, maintaining the high quality standards that distinguish us in the market.

50

Press

total

700

Tonnage from

from 10 to 700 tons

3 Kg

Production from 2 to 3 kg

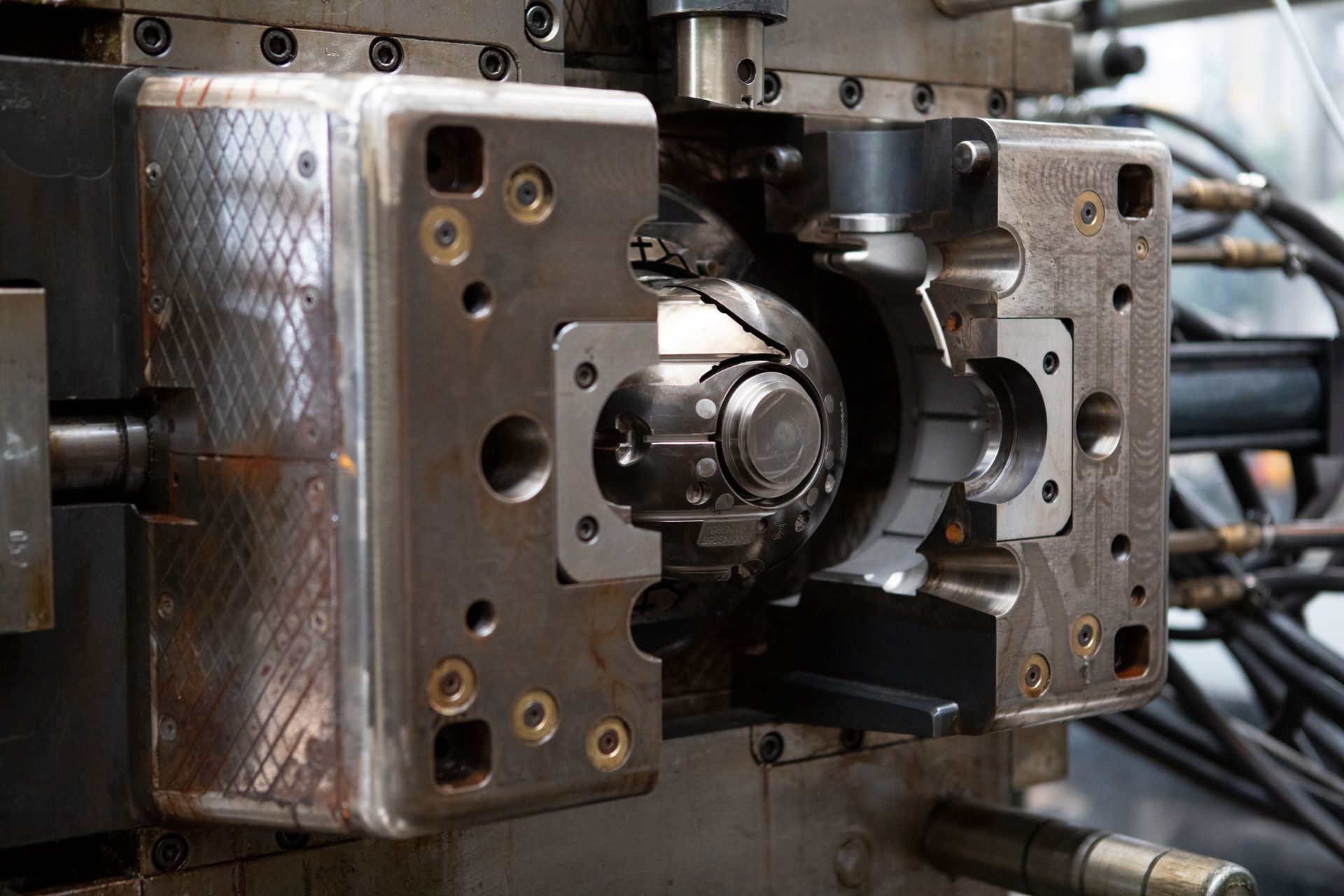

Two-material molding: precision and versatility

We have three dual-material presses with rotary tables, designed to produce complex technical parts by molding two different materials into the same piece, on specific areas of the mold. This advanced technology allows us to produce components with high functional and aesthetic performance, optimizing production times and costs.

Bimaterial overmolding offers numerous advantages, allowing it to meet various needs:

- Aesthetics: creation of two-tone pieces, surfaces with a “soft touch” effect, or items in recycled material enhanced with a new material covering.

- Sealing: greater resistance to pressure and mechanical stress, ideal for high-performance technical components.

- Performance: improved resistance to high temperatures and chemical agents, ensuring durability and reliability even in critical conditions.

Thanks to its experience in the sector and the use of advanced technologies, Plastica Nardon is able to offer customized two-material molding solutions for a wide variety of manufacturing sectors.

4

Presse Bimateria

2 Tables

Rotating

Automation

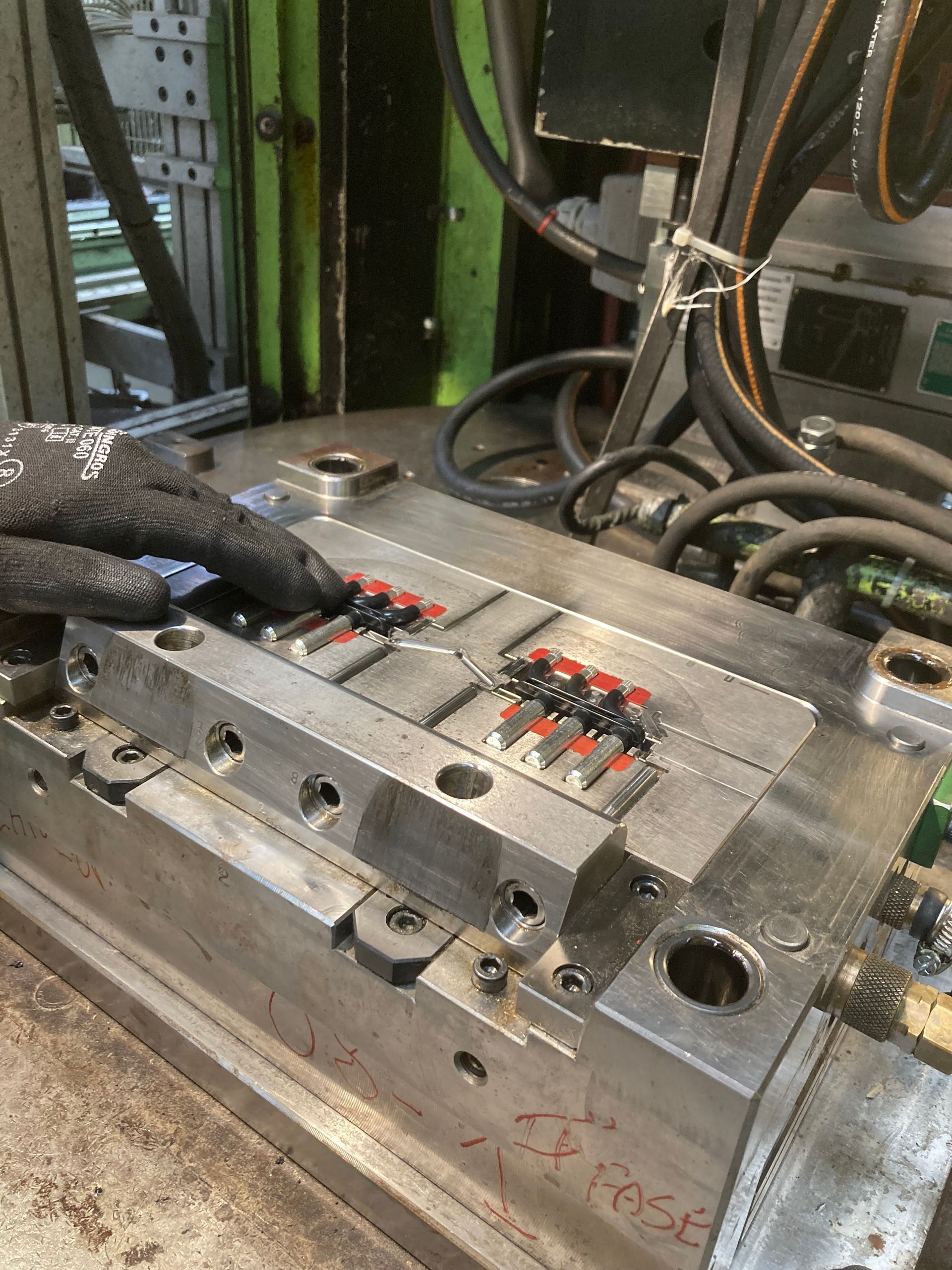

Plastic co-molding

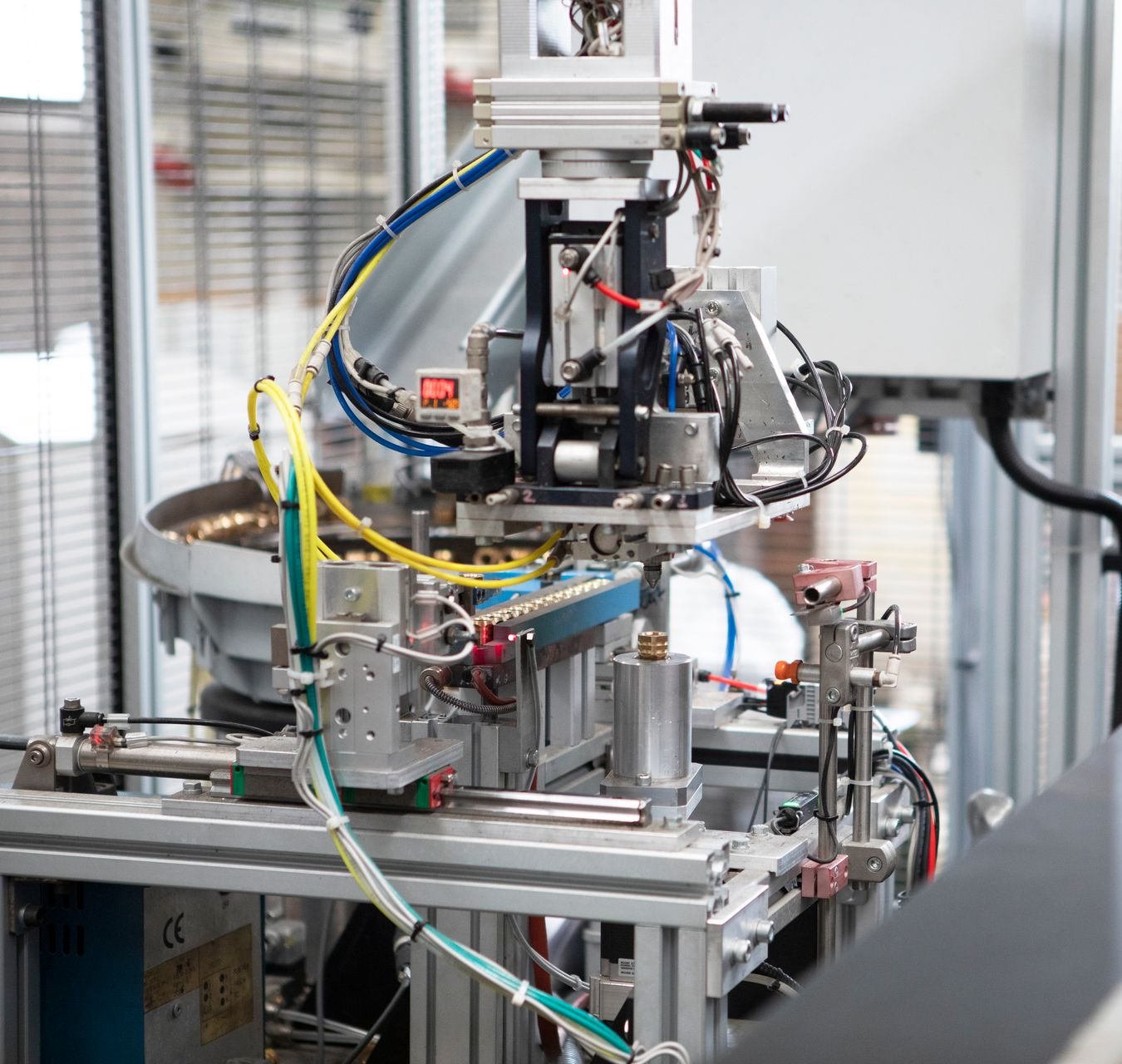

Our production department is equipped with 18 plastic overmolding presses, including 15 horizontal and 3 vertical presses with two- or three-station rotary tables. Each system is integrated with automated loading, inspection, and unloading stations, designed to optimize processing times and ensure maximum repeatability of the production process.

Thanks to the use of vision systems with cameras and control monitors, every single mold is 100% inspected, ensuring extremely high quality standards and consistent final results. Advanced automation and precision technology allow us to offer reliable, high-performance solutions for every plastic molding need.

15

Horizontal Presses

3

2 or 3 station vertical presses

Loading / Unloading

Automated