Our experience at your service

DESIGN

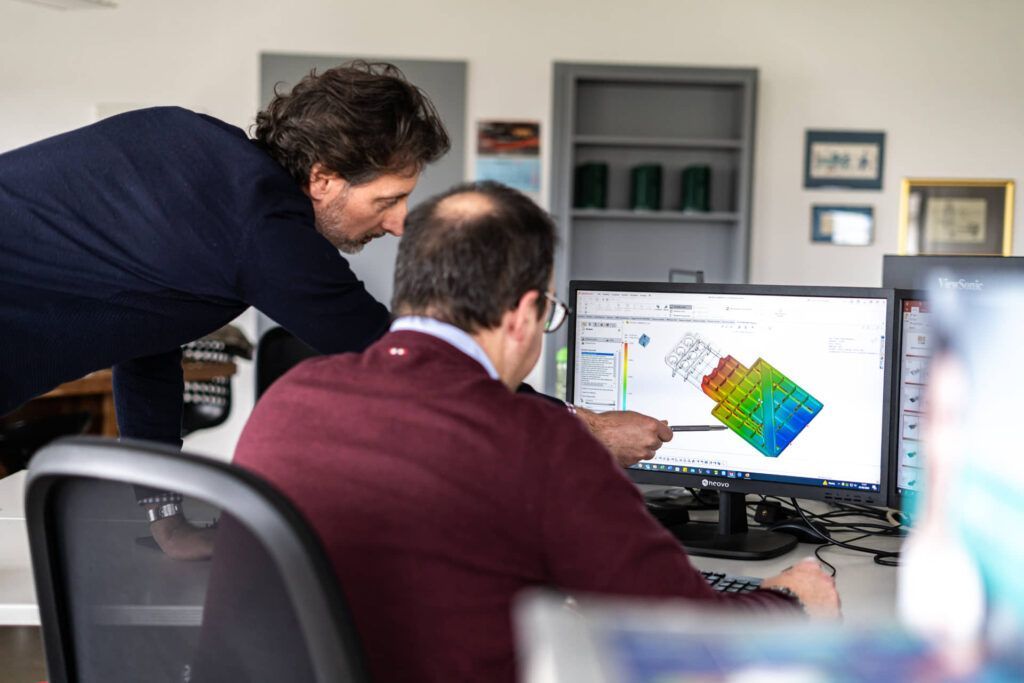

Co-design, study, process simulation and choice of materials

We use cutting-edge CAD software to accurately and precisely reproduce molding operations. Thanks to our advanced 3D simulations, we can virtually verify every tiny detail of the process, allowing us to immediately identify any critical issues and areas for improvement. This proactive approach allows us to resolve issues during the design phase, thus ensuring a high-quality final result. Where necessary, we also perform in-depth filling and deformation analyses to ensure that every aspect of the project is optimized and that the solutions adopted meet expectations and specifications.

Feasibility analysis

Design is a crucial and decisive phase that will significantly impact the quality, efficiency, and maintenance costs throughout the molds' lifecycle. This process requires not only attention, but also in-depth expertise to achieve and ensure, over time, high-performance production both in terms of quality and quantity. It's crucial to consider every detail, as every decision made during this phase will impact the final result. Our team of highly specialized technicians with proven experience in the sector will work with you to develop your idea, transforming it into reality in a few well-defined steps. We will provide you with all the support you need, suggesting optimal solutions at every step of the process, to ensure that the project is not only feasible, but also meets your expectations and needs. We listen to your needs and strive to identify the most efficient solutions to meet them. During this phase, we thoroughly analyze your requirements, the intended use of the product, and the details necessary for its implementation, to verify and define the project's feasibility.

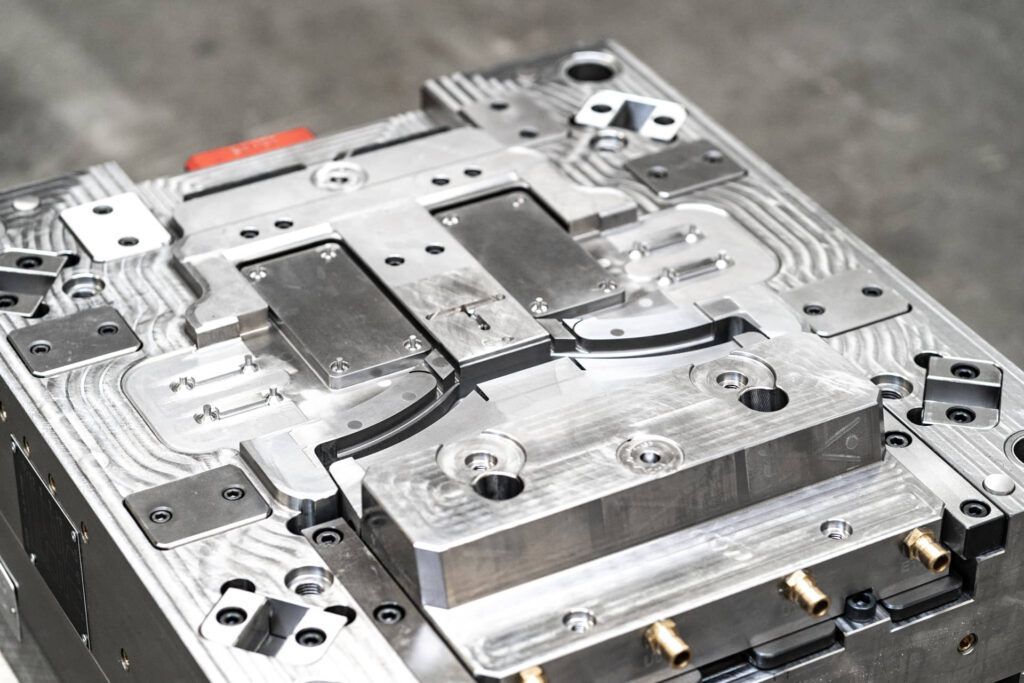

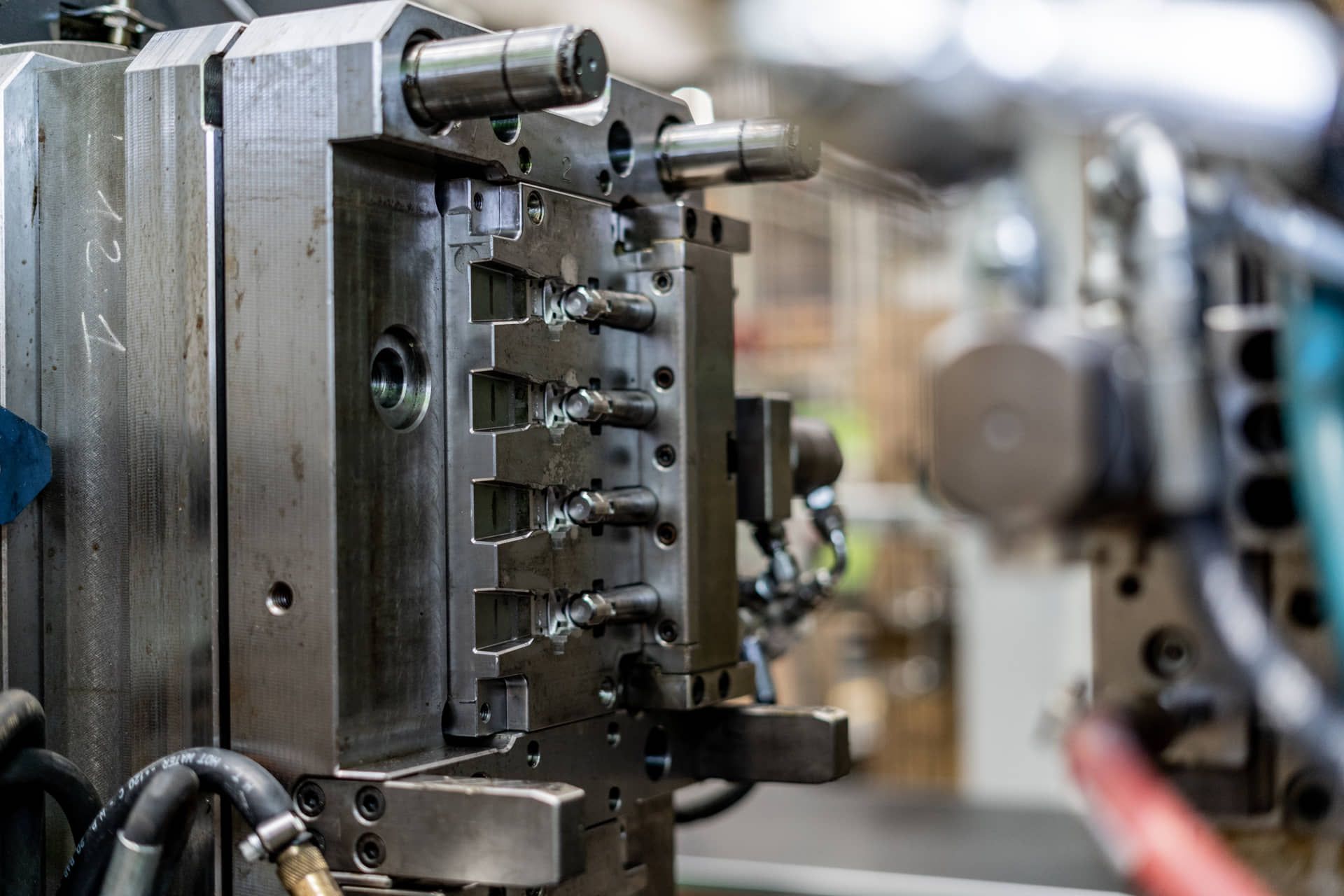

Mold construction and prototyping

We design and build molds in collaboration with top-notch toolmakers, carefully selecting reliable, experienced Italian partners who have long collaborated with us in the production of high-quality molds. Thanks to this synergy, we can guarantee excellent results and solutions tailored to our customers' needs. Upon specific customer request, we also offer the option of building pilot molds. These pilot molds are typically created to optimize and define the construction criteria and functionality of a multi-cavity mold, significantly improving its performance and ensuring more efficient and precise long-term production.